Digital Light Processing, DLP in short, is used to fabricate 3D models, parts, and prototypes. It is sometimes confused with Stereolithography (SLA), another 3D printing technology. You can find out more about SLA and compare the differences here.

How Does DLP work?

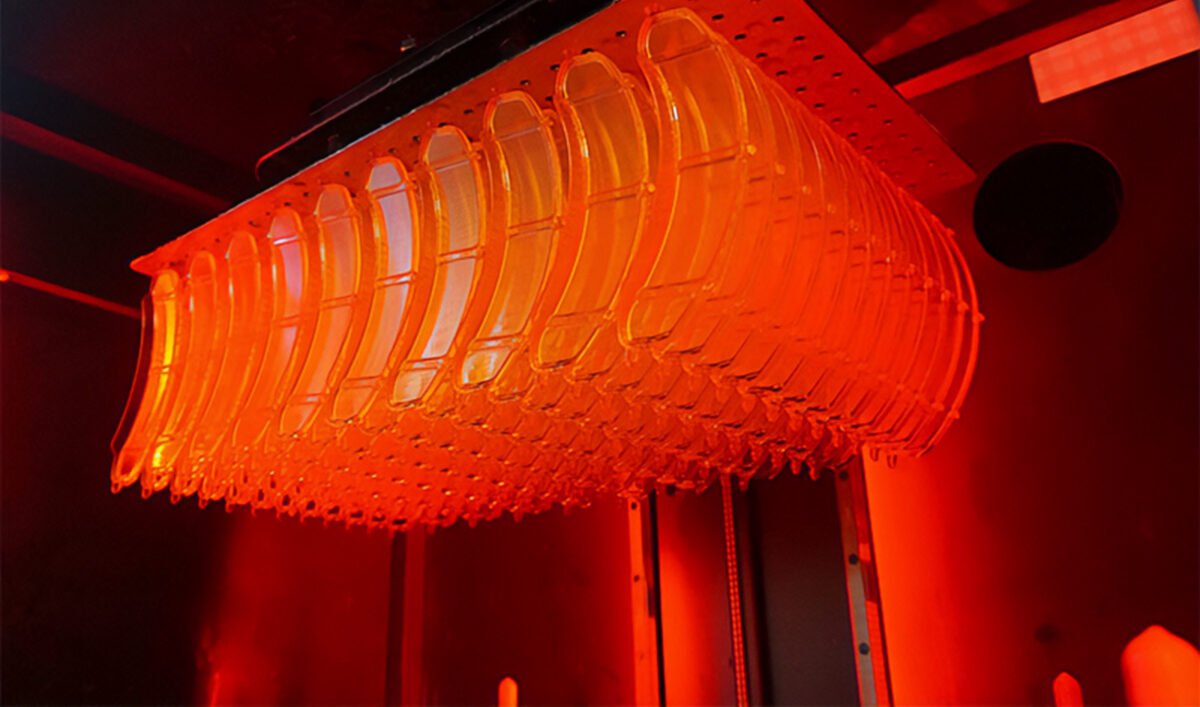

The build platform is placed in a vat of photopolymer (resin). A DLP 3D-printer will then use a digital projector screen to flash an image of light on the entire layer which cures all points simultaneously. This would be done layer by layer until the part is completed. The light is controlled by a device called a Digital Micromirror Device. Which consists of microscopic-sized mirrors laid out in a matrix which is then controlled by a chip. It rapidly toggles the mirrors which helps to define where the light lands by directing the light appropriately to the build platform. Most DLP 3D-printers also build bottom up.

What Material Does DLP Uses?

Photopolymers, also commonly know as resins, are used as the initial material is required to be liquid and needs to be sensitive to light. However, the manufacturer of the machine determines the types of resins that are supported by their printers. A general guide of the different types of resins are:

- Standard Resins

- Engineering Resins,

- Dental and Medical Resins

- Castable Resins.

For a more in-depth look of the materials, click here.

Advantages

High Accuracy And Detailing

The resolution of DLP 3D-printers is determined by the resolution of the projector used. As such, the resolution is usually around 0.04-0.1mm. Although there are factors that will affect how accurate a part is, DLP prints are one of the most accurate compared to the other 3D-printing technologies.

Speed Of Prints

Since DLP 3D-printers work cures the whole layer at the same time, the speed of print is generally quite fast. The final speed and detailing of the build is then solely determined by the layer height.

Disadvantages

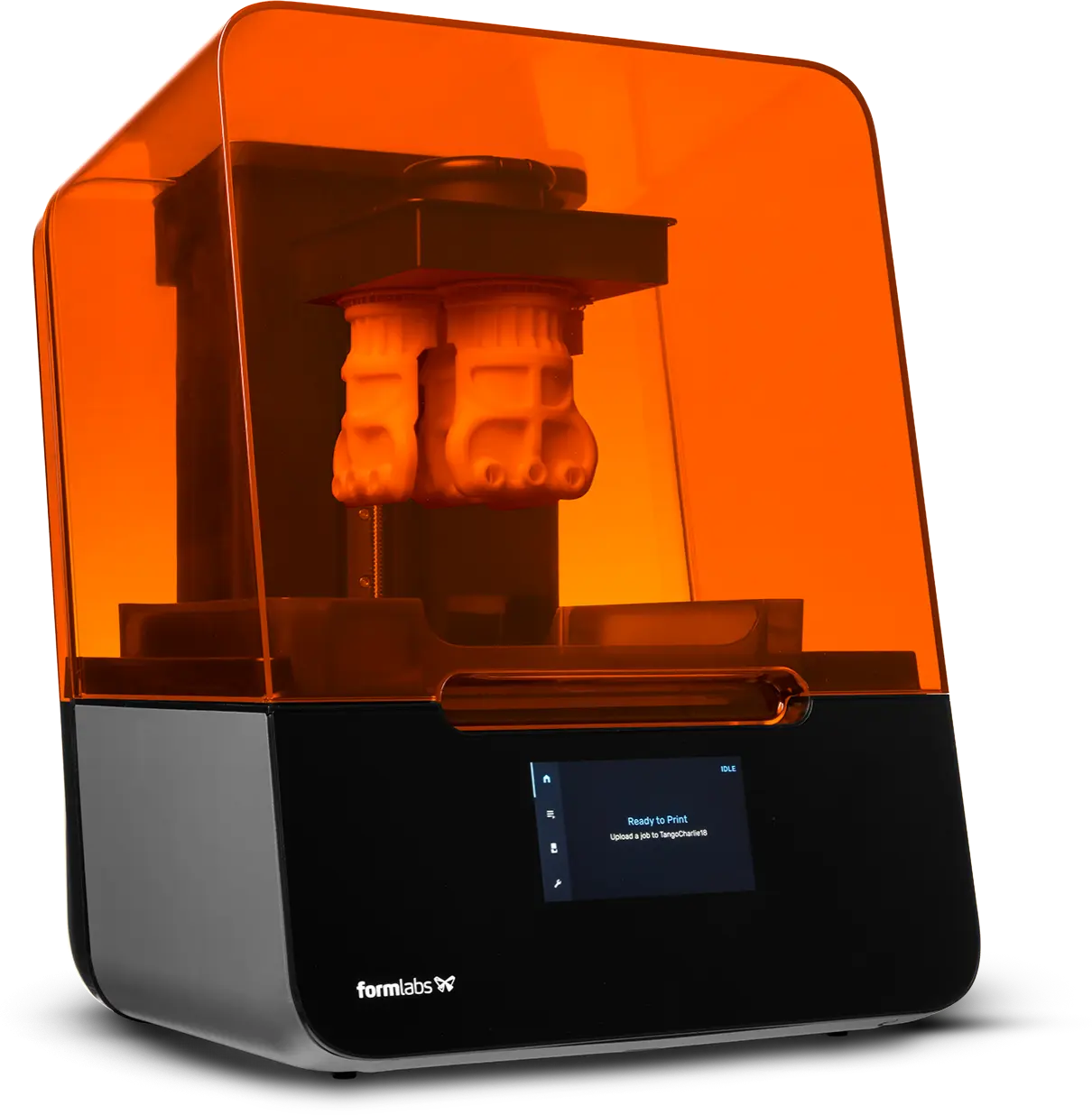

High Cost

Although there are some budget options out there, the general starting cost for the machine alone is quite high as compared to an FDM machine with the same build space.

But the cost really starts to add up when you factor in the material cost. Resins for the DLP 3D-printers are significantly higher; costing almost SG$200 – SG$250 per litre of resin.

The post-processing of DLP parts will also require additional equipment. This drives up the initial cost of owning and operating the machine.

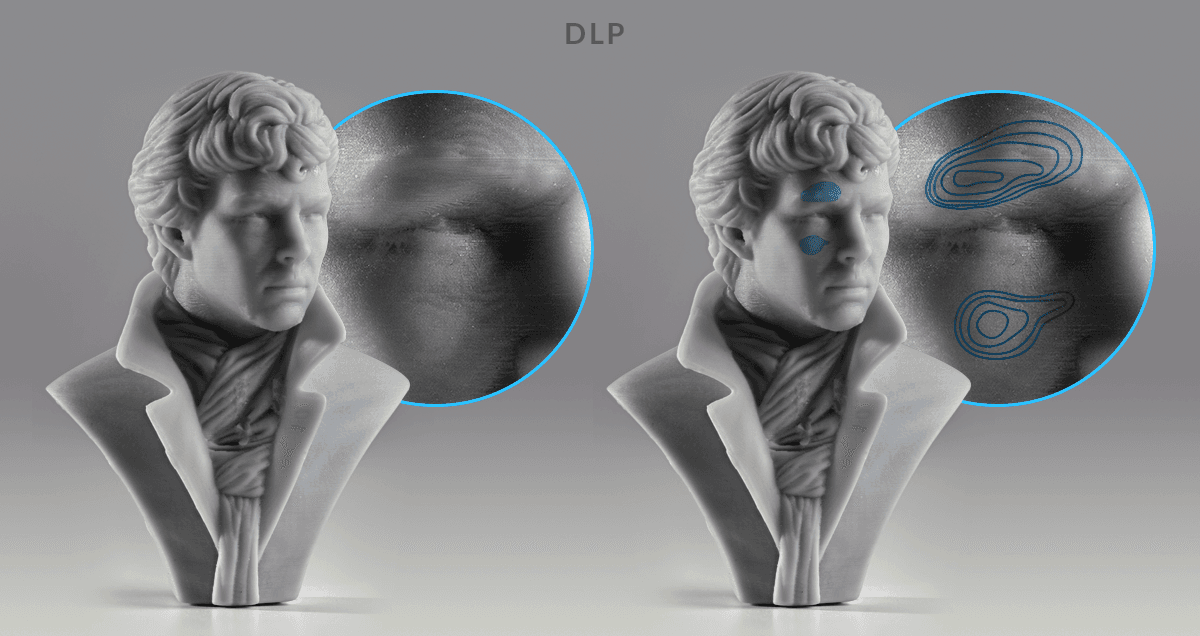

Post-Processing

After the print is done, 3D-printed DLP parts will have excess liquid resin that has to be removed. Depending on the detailing of the print, small crevices and holes may make the print difficult to clean. Generally, dealing with liquids makes the process messier and more time-consuming. Additional time will also be required to remove supports. Due to the way DLP parts are printed, the surface comes out ‘boxy’. To achieve a better surface finishing and surface roughness, like that of SLA 3D printed part, you will need additional processes to achieve a similar finish.

Material Has Limited Properties And Colours

Over the years, different types of resins have been developed for DLP 3D-printed to ensure that it has better mechanical properties in comparison to parts 3D-printed on different technologies. However, at present, the mechanical properties still does not match up to that of other 3D-printed technologies. The resin also comes in limited colours which may be a concern to some people.

Get your parts 3D Printed today! Need help to decide? Contact us and we will get back to you.

Some links to articles are not live yet, please be patient while we continuously update our site with new articles and this post if there are any new developments.